The Role of a Galvanometer Scanner in Improving Information Purchase Performance

Galvanometer scanners function as pivotal elements in the world of data acquisition, specifically because of their capacity to accomplish accurate and quick positioning of reflective elements. This ability not only speeds up the scanning procedure but also boosts measurement accuracy via innovative responses mechanisms. Industries varying from biomedical to making progressively depend on these tools for effective information collection. The effects of their assimilation extend past mere effectiveness; they welcome a closer evaluation of their operational mechanisms and the future technologies that might further change data purchase methods.

Understanding Galvanometer Scanners

Using exact electromagnetic principles, galvanometer scanners work as crucial devices in data acquisition systems, making it possible for the precise measurement and recording of electric signals. These devices are designed to convert electrical signals into mechanical movement, which can after that be envisioned or videotaped. The fundamental characteristic of a galvanometer scanner is its ability to respond to variations in existing, allowing it to discover minute changes in electric signals with high level of sensitivity.

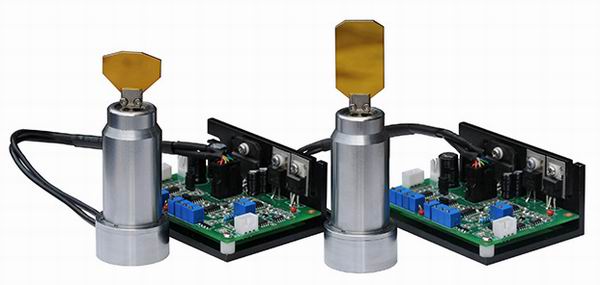

Galvanometer scanners are pivotal in a selection of applications, consisting of biomedical research study, optical scanning, and quality assurance procedures in manufacturing. Their capacity to deliver reputable and rapid analyses makes them suitable for environments that require high precision and quick response times. In addition, the building and construction of galvanometer scanners usually consists of a light-weight coil put on hold in an electromagnetic field, allowing them to achieve high angular deflection with marginal inertia.

The adaptability of galvanometer scanners permits assimilation into various information procurement systems, improving the general efficiency of signal measurement. By making sure precise and rapid analyses, these devices substantially add to the dependability of information analysis, which is essential in both clinical research and industrial applications.

Mechanism of Procedure

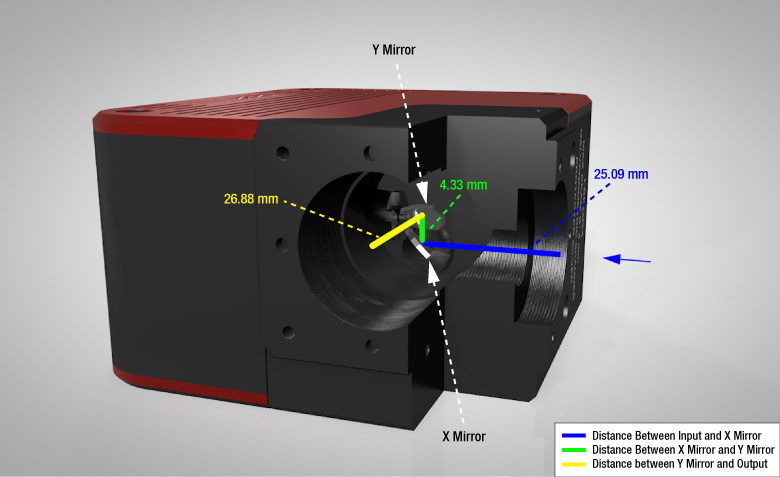

The operation of a galvanometer scanner depends on the interaction between magnetic areas and electric currents to produce mechanical movement (galvanometer scanner). At its core, the gadget includes a coil put on hold within an electromagnetic field. When an electric existing travel through the coil, it generates a magnetic field that communicates with the external electromagnetic field, resulting in torque that causes the coil to rotate. This rotation is normally gauged in levels, allowing for accurate angular variation.

The input current's variation directly affects the angle of deflection, allowing the scanner to react properly to changes in the input signal. By controling the current's strength and instructions, the galvanometer scanner can accomplish rapid and exact positioning of a reflective aspect, such as a mirror. This capability is critical in applications needing accurate alignment and scanning, as it assists in the regulated motion of beams or various other signals.

The responses mechanism integrated within numerous galvanometer scanners further improves their accuracy. Sensors check the setting of the coil, giving real-time information that can be made use of to change the existing dynamically. This closed-loop control system guarantees that the scanner keeps accuracy throughout its operational variety.

Applications in Various Industries

Galvanometer scanners discover substantial applications throughout various industries because of their accuracy and fast response abilities. In the area of telecommunications, they are indispensable to laser beam of light steering for optical networking, allowing high-speed information transmission. Medical diagnostics additionally profit considerably from galvanometer scanners, as they are employed in laser-based imaging systems, such as Optical Coherence Tomography (OCT), offering high-resolution pictures for much better diagnosis.

Furthermore, in scientific study, galvanometer scanners are crucial for laser scanning microscopy, allowing scientists to record in-depth photos of organic samplings and products. They are likewise employed in metrology for high-precision measurements, making sure compliance with rigorous sector requirements. Overall, the flexibility and efficiency of galvanometer scanners make them indispensable throughout varied fields, substantially adding to innovations in technology and top quality guarantee.

Benefits for Information Acquisition

In data procurement procedures, the consolidation of galvanometer scanners dramatically improves measurement accuracy and speed. These devices make use of high-precision mirrors and quick angular motions to guide laser beam of lights or light sources with amazing accuracy, which is crucial for applications requiring exact positioning and timing.

The versatility of galvanometer scanners permits for smooth combination right into different information acquisition systems, adapting to specific demands in areas such as biomedical imaging, materials screening, and ecological surveillance. This flexibility not just enhances the versatility of the devices yet likewise maximizes the total effectiveness of information collection workflows.

In addition, the portable layout of galvanometer scanners promotes simple installment and maintenance, more adding to functional performance. Inevitably, the advantages of using galvanometer scanners in information go to this web-site purchase processes equate to much better high quality information, minimized functional costs, and enhanced task turnaround times.

Future Trends and Innovations

Advancements in modern technology are positioned to drive the development of galvanometer scanners, additionally boosting their duty in data procurement. Emerging developments are likely to concentrate on raising scanning rates and enhancing accuracy, permitting for extra effective information collection in applications varying from biomedical imaging to industrial automation.

Integration of expert system and artificial intelligence formulas is anticipated to play an important function in optimizing scanner efficiency. These modern technologies can allow real-time adjustments throughout the scanning process, enhancing accuracy and decreasing errors. The consolidation of innovative materials, such as lightweight composites, can lead to the development of even more dexterous scanners with improved responsiveness.

In addition, the trend toward miniaturization will likely result in small galvanometer systems, making them a lot more easily accessible for various applications, including portable devices. Boosted connectivity via IoT assimilation can facilitate smooth data transfer and remote surveillance, additional simplifying data procurement procedures.

As the demand for high-resolution imaging and fast data handling proceeds to expand, galvanometer scanners will advance to fulfill these needs, positioning themselves as vital devices in the mission for performance throughout numerous areas. The future assures a transformative journey for galvanometer innovation, driven by advancement and accuracy.

Verdict

In verdict, galvanometer scanners significantly enhance data procurement effectiveness via their quick and precise placing capacities. As industries proceed to integrate these scanners into their systems, recurring innovations and fads are anticipated to further optimize their performance, strengthening their vital function in the evolution of information acquisition modern technologies.

Galvanometer scanners serve as pivotal components in the realm of data purchase, specifically due to their ability to attain exact and fast positioning of reflective elements.Using specific electro-magnetic concepts, galvanometer scanners offer as important tools in data acquisition systems, allowing the accurate measurement and recording of electrical signals. On the whole, the versatility and effectiveness of galvanometer scanners make them crucial across varied sectors, substantially adding to advancements in innovation and quality guarantee.

One of the main advantages this article of galvanometer scanners is their capability to attain high-speed data collection.In final thought, galvanometer scanners substantially learn the facts here now improve information acquisition effectiveness with their accurate and rapid positioning capacities.